Today, numerous efforts have been made in automating front-end operations at Fuel Stations. Processes such as fuel consumption tracking, custody transfer, and billing have successfully transitioned to automated systems. However, despite these advancements, a critical gap remains in the automation and digitalization of various backend systems. This oversight not only poses safety risks but also undermines potential cost savings.

To address this gap effectively, the implementation of a centralized monitoring platform for the Fire System at Fuel Stations could greatly enhance safety measures. Such a platform would enable real-time monitoring, early detection of anomalies, and swift response to potential hazards, thereby strengthening overall operational safety.

Additionally, deploying a Maintenance Planner for Auxiliaries would streamline maintenance scheduling and optimize resource allocation. By leveraging predictive analytics and condition-based maintenance techniques, this system can minimize downtime, reduce maintenance costs, and prolong the lifespan of critical equipment encouraging sustainability.

By embracing digitalization and automation in both front-end and backend operations, Fuel Stations can maximize efficiency, mitigate risks, and achieve long-term sustainability.

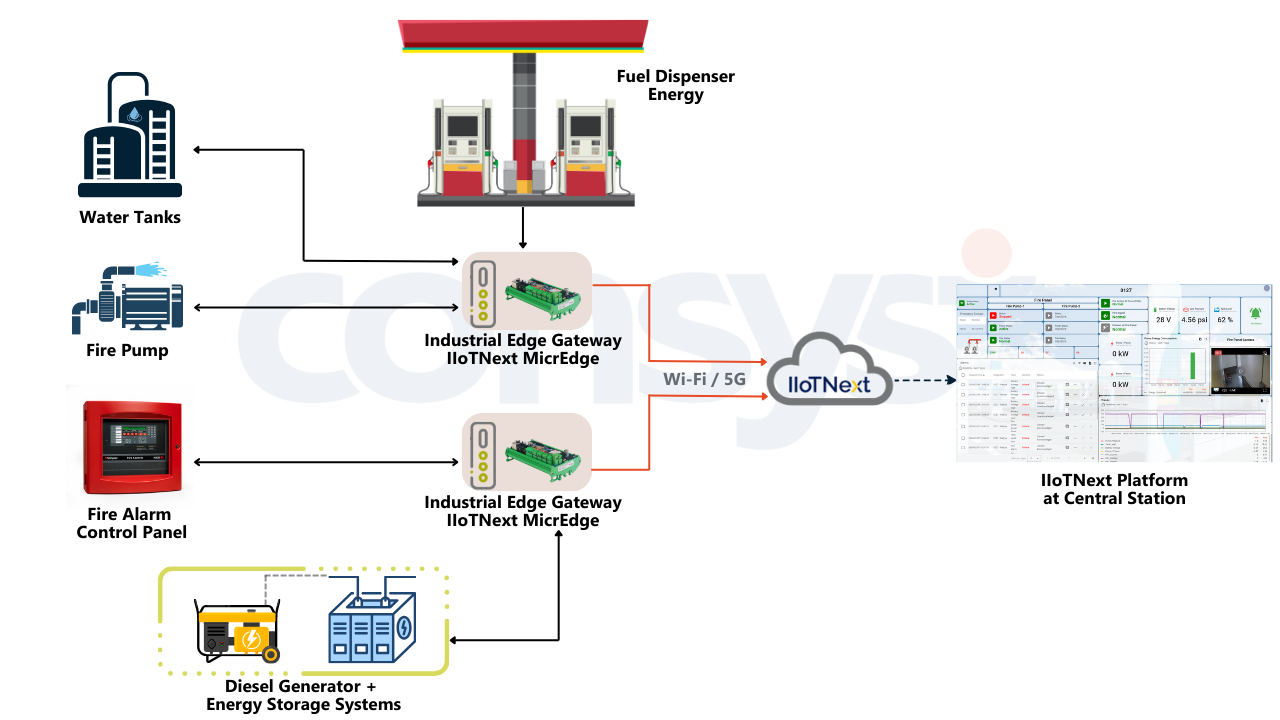

Distributed Assets at a Fuel Station that may benefit from remote and centralized monitoring:

- Water Pumps (part of the Fire and Safety System)

- Fuel Storage Tanks

- Diesel Generators (part of the Power Supply System)

- Fuel Dispensers

- Lighting Systems

The diverse range of parameters, spanning from power output fluctuations, water & fuel levels to energy consumption metrics, creates a data pool difficult to interpret and manage efficiently. The fragmented approach not only delays real-time decision-making but also increases the risk of oversight delaying the need to address critical issues across these varied assets.

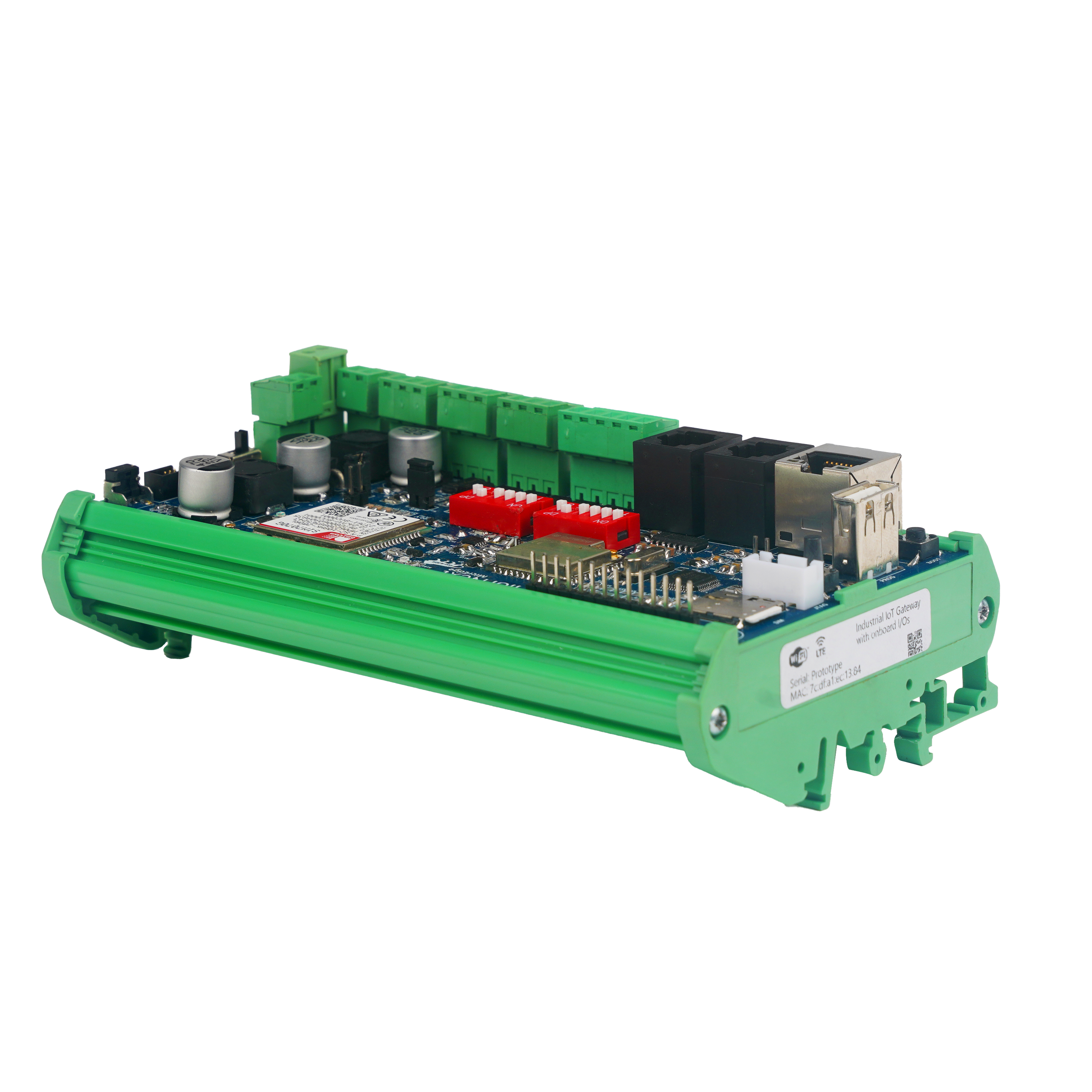

Facilitating a seamless integration of the assets indicated above, the IIoTNext MicrEdge —is a cutting-edge solution designed to fetch real-time data from each asset efficiently. Acting as a sophisticated data aggregator at the edge, the MicrEdge captures and compiles critical information and further facilitates the seamless transfer of this comprehensive data to the IIoTNext Platform for real-time visualization

As an Industrial IoT Gateway with On board IOs, the IIoTNext MicrEdge leverages LTE/Wireless connectivity for internet access, SIM cards for GSM connectivity, Modbus RTU, and CAN Bus over RS485, alongside Hardwired I/Os for device and instrument connection. The incorporation of various communication technologies into a single board highlights the MicrEdge's unique positioning in the industry today.

With the IIoTNext MicrEdge seamless integration of water pumps, canopy lights, and other assets is made effortless through its onboard IOs and versatile communication capabilities across multiple technologies.

The MicrEdge's compact design allows for seamless integration within a Data Acquisition Panel or existing panel, and its compatibility with Rails ensures easy mounting on the backplate of control panels or junction boxes.

The IIoTNext Platform serves as the central nervous system where the collected data from IIoTNext MicrEdge is processed, analyzed, and presented in a unified, real-time visualization. The integration not only empowers operators with a holistic view of distributed asset parameters but also facilitates quick identification of anomalies, predictive maintenance insights, and informed decision-making.

Key features of the platform include:

- Remote Monitoring: Operators can remotely monitor assets from anywhere, enabling timely intervention and optimization of operations.

- Multiple User Accounts with Role-Based Access Control: The platform supports multiple user accounts, each with customized access rights based on predefined roles, ensuring data security and confidentiality.

- Historical Data Access and Analysis: Users can access historical data for in-depth analysis, trend identification, and performance evaluation, facilitating data-driven decision-making.

- Alarms and Notifications on Critical Events: The platform generates real-time alarms and notifications for critical events, such as equipment failures, abnormal readings, or safety breaches, enabling prompt action and mitigation of risks

Centralized Monitoring of Distributed Assets at a Gas Station

How IIoTNext can improve visibility for your distributed assets:

By leveraging advanced functionalities of the IIoTNext MicrEdge and IIoTNext Platform together, Fuel Station operators can proactively manage assets, plan inventories, plan for asset maintenance and thereby enhance operational efficiency to maintain a safe and reliable environment. If you are looking to digitalize and centralize monitoring operations at a Fuel Station, contact us today.