End-User: Milma, India

Milma is one of the leading dairy cooperative societies in the country. As of date, there are 13 milk processing plants with a combined processing capacity of 13 lakh liters per day with further expansion envisaged and 8 Milk Chilling Plants scattered across the State.

Milma operates many cold storage facilities across the state in order to support its supply chain. The cold storages are responsible for the preservation and transportation of a range of perishable dairy food products in the proper temperature range. This is to slow down the biological decay process and deliver safe and high‐quality foods to consumers.

Challenges

The milk storage facilities are expected to be kept at a particular temperature in order to ensure the quality of dairy products. Interruptions in compressor operation and failure in manual temperature monitoring in the facility can cause the temperature to go high and not be maintained as per requirements.

- Unnoticed temperature variation above the optimal product‐specific range, a situation that significantly increased food wastage and endangered food safety.

- The lack of real-time visibility of cold storage contributed to inefficient operational processes and created surprise failures in the supply chain.

- Manipulation of data from local cold storage kept management ill-informed and hindered them from making the right decisions and swift actions.

Solution

System description:

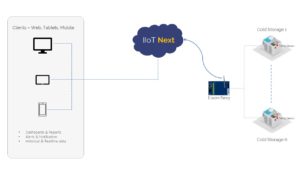

IIoT Next offers a cloud-based solution. It provides out-of-the-box components and APIs to dramatically drive down the effort required to create remote monitoring solutions. The SMS and email communication on critical events enable the management personnel to take quick decisions.

- Data collection from each cold storage using remote i/o via Modbus communication protocol through IIoT Gateway.

- Data is pushed from IIoT Gateway using https rest API to the IIoT Next cloud platform.

- Reliable and fault-tolerant data collection for the cold storage temperature sensors through Ewon flexy deployed as the IIoT Gateway.

- Advanced and flexible IoT data visualization dashboard for both real-time and historical temperature data.

- Alarm features to instantly notify management personnel about any critical events or unusual temperature levels.

- Data visualization, alarms for each asset made available on the web, and mobile app.

Benefits:

- Maximized the efficiency of cold storage units

- Significant reduction in food wastage and security issues.

- Avoid issues with manual data manipulation and surprise failures.

- Enable management to take informed quick decisions.

- Advanced and feature-rich data visualization.