Remotely monitor, manage, and control Gensets on the go. Gain real-time insights and ensure fail-safe operation without manual interventions, all while maintaining operational efficiency.

Introduction

Diesel Generator (DG) sets are crucial for providing backup power across various industries including Oil & Gas, Telecom etc. Rental companies who rent these generators face significant challenges in ensuring their reliable and efficient operation. The advent of Industrial Internet of Things (IIoT) gateways has transformed the monitoring and control of DG sets, addressing many of these challenges. This article examines the challenges faced, the critical parameters for monitoring, and the necessary control actions to ensure the fail-safe and automatic operation of DG sets.

Challenges faced by DG Set rental companies:

- Operational Efficiency

- Optimizing fuel consumption and managing refueling schedules.

- Maintaining optimal performance for varying power demands.

- Ensuring high reliability and minimal downtime.

- Fail-Safe Operation

- Ensuring DG sets can be turned on or off as needed to avoid fuel wastage and operational inefficiencies when internet connectivity is lost, maintaining uninterrupted control and optimal resource usage.

- Manual Intervention

- Frequent on-site visits needed for monitoring and manual control.

- Increased operational costs and slower response times.

- Real-time Remote Monitoring and Management

- Ensuring reliable monitoring and control of DG sets in various locations.

- Difficulty in tracking real-time performance and maintenance needs.

- Maintenance and Repairs

- Scheduling and conducting timely maintenance and repairs.

Solution

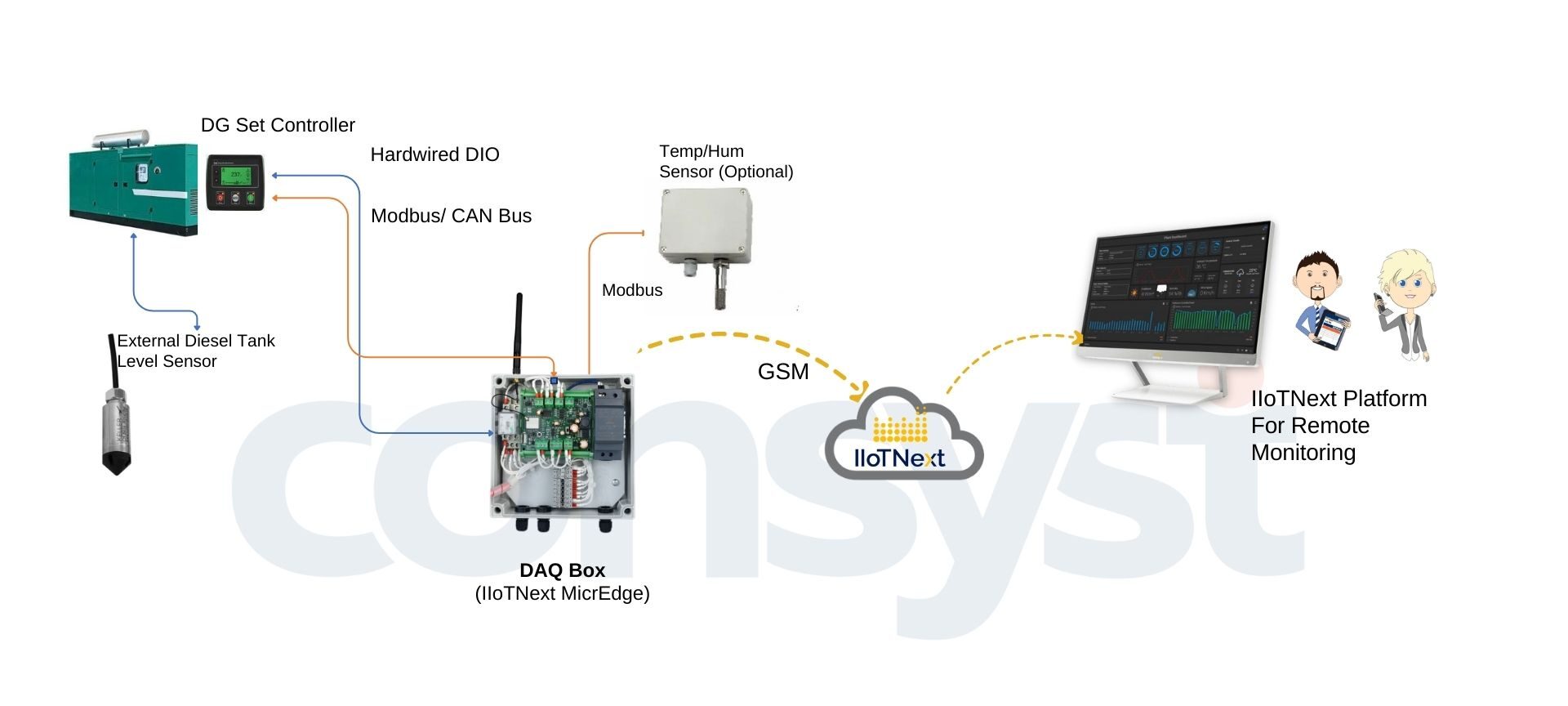

The The IIoTNext MicrEdge is a cutting-edge Industrial IoT Gateway designed to capture real-time data from each DG set. It aggregates critical information and ensures the seamless transfer of this comprehensive data to the IIoTNext Platform for real-time visualization and control.

The IIoTNext MicrEdge uses LTE/Wireless connectivity for internet access. It supports Modbus RTU and CAN Bus over RS485, along with hardwired I/Os for direct connection to DG sets and sensors. The MicrEdge's compact design allows for seamless integration within a Data Acquisition Panel or existing panel, through easy mounting on the backplate of control panels or junction boxes.

This integration of diverse communication technologies into a single board distinguishes the MicrEdge as a uniquely versatile and powerful solution in today's industry.

The MicrEdge can not only offer easy integration to collect data but also support to provide a fail-safe control action through SMS remote control, customized logic or automated schedules. This ensures that DG sets can be managed effectively even during internet connectivity disruptions, allowing for timely on/off commands to prevent unnecessary fuel consumption. Additionally, the MicrEdge's ability to execute predefined control logic and schedules enhances operational reliability by automating responses to changing conditions, thereby minimizing the need for manual intervention.

The IIoTNext Platform functions as the core system where data collected from the IIoTNext MicrEdge is processed, analyzed, and displayed in real-time visualizations. This integration provides operators with a comprehensive overview of distributed DG Set critical parameters, enabling quick anomaly detection, maintenance insights, and well-informed decision-making.

Key features of the platform include

- Multiple User Accounts with Role-Based Access Control : The platform accommodates multiple user accounts, each with tailored access rights based on predefined roles, ensuring data security and confidentiality.

- Remote Monitoring: Operators can monitor assets remotely from any location, allowing for timely interventions and the optimization of operations.

- Historical Data Access and Analysis: Users can access historical data for in-depth analysis, trend identification, and performance evaluation, facilitating data-driven decision-making.

- Alarms and Notifications on Critical Events: The platform generates real-time alarms and notifications for critical events, such as equipment failures, abnormal readings, or safety breaches, enabling prompt action and mitigation of risks.

- Scheduling Maintenance / Condition based maintenance: A Preventive Maintenance Planner module can be designed to streamline maintenance operations. This feature tracks maintenance frequencies, records last maintenance dates, and presents a prioritized list of DG sets requiring upcoming maintenance activities through an interactive dashboard. By providing timely and organized maintenance insights, this module saves time and money for the maintenance team, ensuring optimal performance and longevity of the equipment.

- Geo fencing: With geofencing on DG Sets (utilizing the position of cell towers to create virtual boundaries (fences) for SIMs), the IIoTNext platform enables precise location tracking and management of DG sets. This feature ensures that DG sets remain within designated areas, providing alerts if they move outside predefined boundaries. It enhances security by preventing unauthorized movement and theft.

- Remote Control: The IIoTNext Platform enables remote management of DG sets, allowing users/operator to switch them on or off and perform other critical control actions. This functionality enhances operational efficiency and flexibility.

System Architecture

By leveraging the IIoTNext MicrEdge and IIoTNext Platform, DG set rental companies can ensure the fail-safe operation of their assets, optimize fuel consumption, reduce manual interventions, scheduled/condition-based maintenance and enhance overall operational efficiency. The real-time monitoring and automated control features minimize downtime and operational costs, while the predictive maintenance insights help prevent potential failures before they occur. This comprehensive approach not only boosts productivity but also extends the lifespan of the DG sets, ensuring a more sustainable and reliable power supply solution.

Ready to revolutionize your Assets IoT? Connect with us today iiotnext@consyst.biz to schedule a demo and learn how our tailor-made solutions can help unlock full potential.