End User: Karnataka Power Corporation Limited (KPCL), India

Karnataka Power Corporation Limited (KPCL), is an electrical power generating company owned by the government of Karnataka. The modes for the generation of electric power are hydroelectric, thermal, diesel, gas, wind, and solar. KPCL began its journey with a humble beginning in 1970 with an installed capacity of 746 MW which has expanded its capacity to 8738.305 MW in 2019.

Challenges

The fly ash, a residue of the burning of pulverized coal and lignite, is generated at thermal power plants, requires large areas of precious land for its disposal, and is also a threat to land and water. The effective management of fly ash has been troublesome in view of its disposal in all thermal power plants.

Integrating IoT in Fly Ash Management is one of the prominent methods for effective utilization of this environmentally hazardous substance. Differences in technology and organizational structure have created persistent challenges between OT and IT environments particularly while integrating data from OT systems like PLC and DCS to Ash Management software. The lack of real-time visibility of Fly Ash generated at various units at the power plant was another barrier to OT-IT convergence.

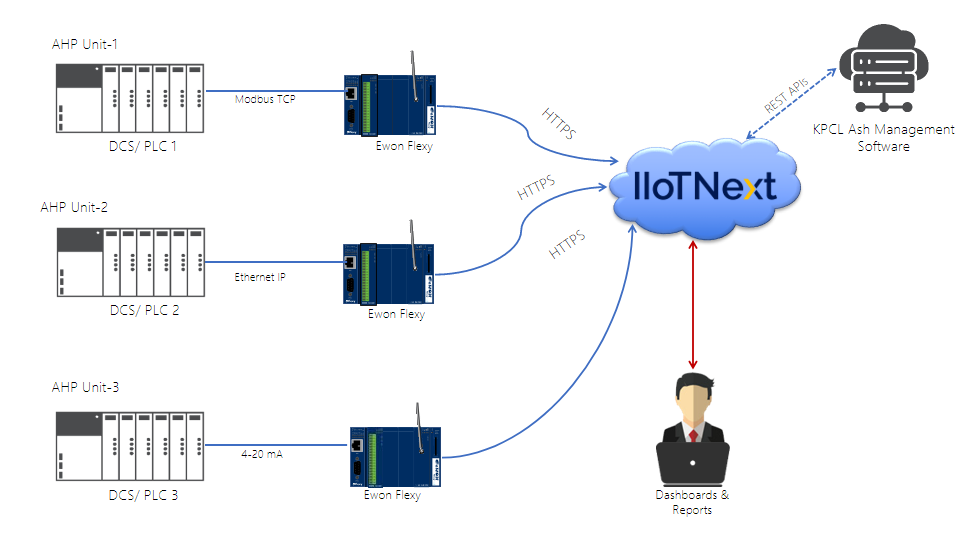

System Architecture

System Description

CONSYST implemented advanced fly ash handling formula by collaborating IIoTNext with the fly ash management software of the plant. IIoTNext cloud Platform collects the data from edge devices through secure HTTP protocol. Each of the edge devices is integrated into existing OT systems like PLC and DCS through standard industrial communication protocols and hardwired IO signals.

Data is collected at the edge device through Modbus TCP, Ethernet IP, and hardwired Analog signals, and it is transferred from the edge device to the IIoTNext cloud platform through secure HTTPS communication. Ewon flexy is deployed as the IIoT Gateway for reliable and fault-tolerant data collection at the sites. Advanced and flexible IoT data visualization dashboard is installed for both real-time and historical data like wet ash, running hours, dry ash running hours, etc. Standard REST APIs are integrated with KPCL Ash Management software.

Benefits

- Provided seamless integration of data from OT to IT system which enabled availability of data for multiple purposes.

- Effective Ash monitoring and managing are enabled by analyzing plant-wise and utility-wise data from Ash Management software.

- Real-time & historical visualization of Ash generation through IIoTNext platform.